Sand, an unavoidable byproduct of oil and gas extraction, poses a significant threat to the integrity and efficiency of production equipment. To combat this, sand separators, also known as sand traps, play a pivotal role in removing sand particles from the production stream. There are three primary types of sand separators: cyclonic, gravity, and spherical.

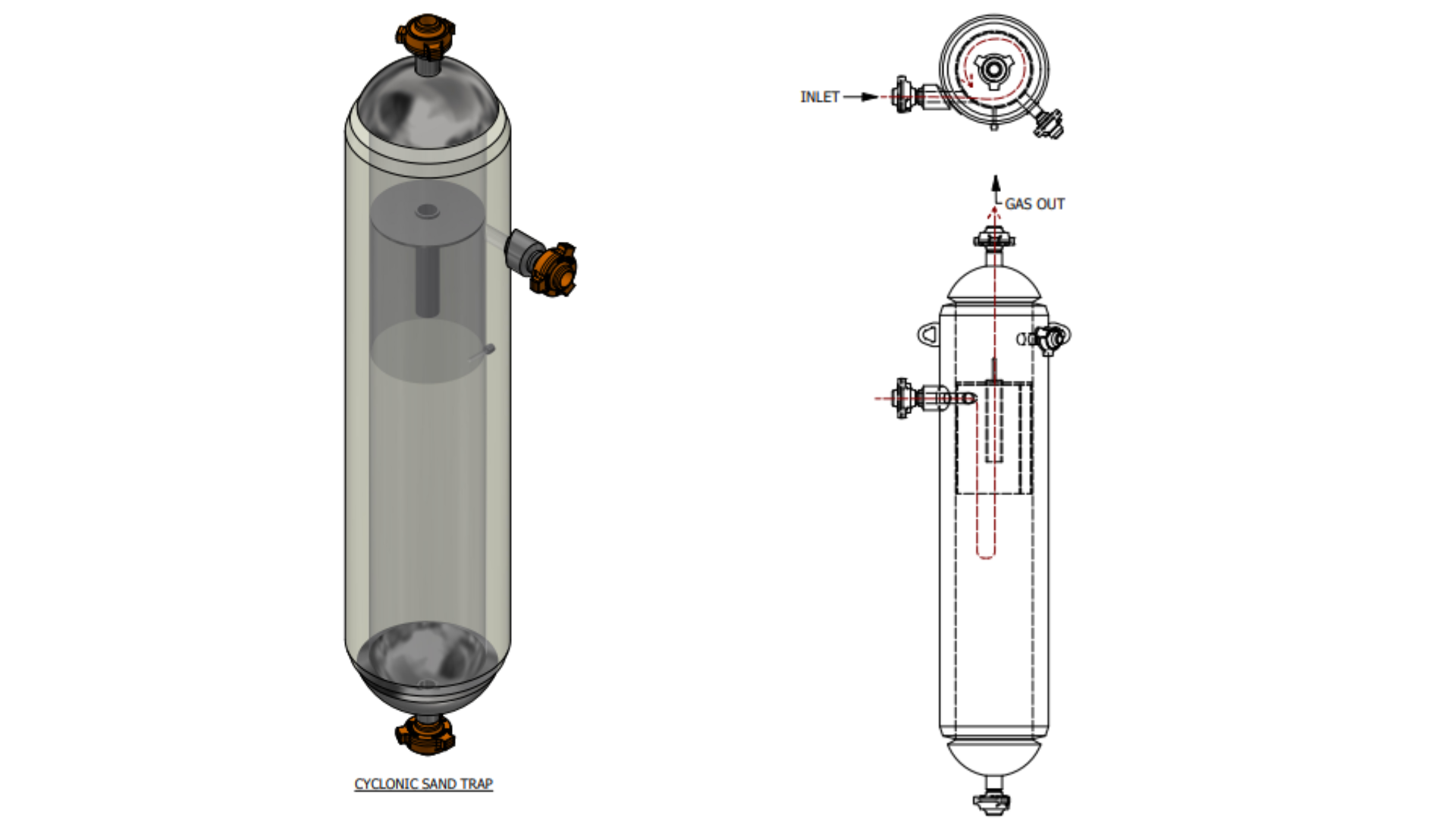

1. Cyclonic Separators

Cyclonic separators are widely employed in the oil and gas industry due to their high efficiency and relatively compact size. They operate on the principle of centrifugal force. The incoming fluid, laden with sand particles, is tangentially introduced into the cylindrical body of the separator, generating a swirling vortex. The heavier sand particles, driven by centrifugal force, migrate towards the outer wall of the separator, where they lose momentum and fall to the bottom collection chamber. The cleaned fluid, devoid of sand, exits through the top outlet.

Cyclonic separators are particularly effective in handling high flow rates and a wide range of sand particle sizes. They are commonly used in both onshore and offshore production facilities.

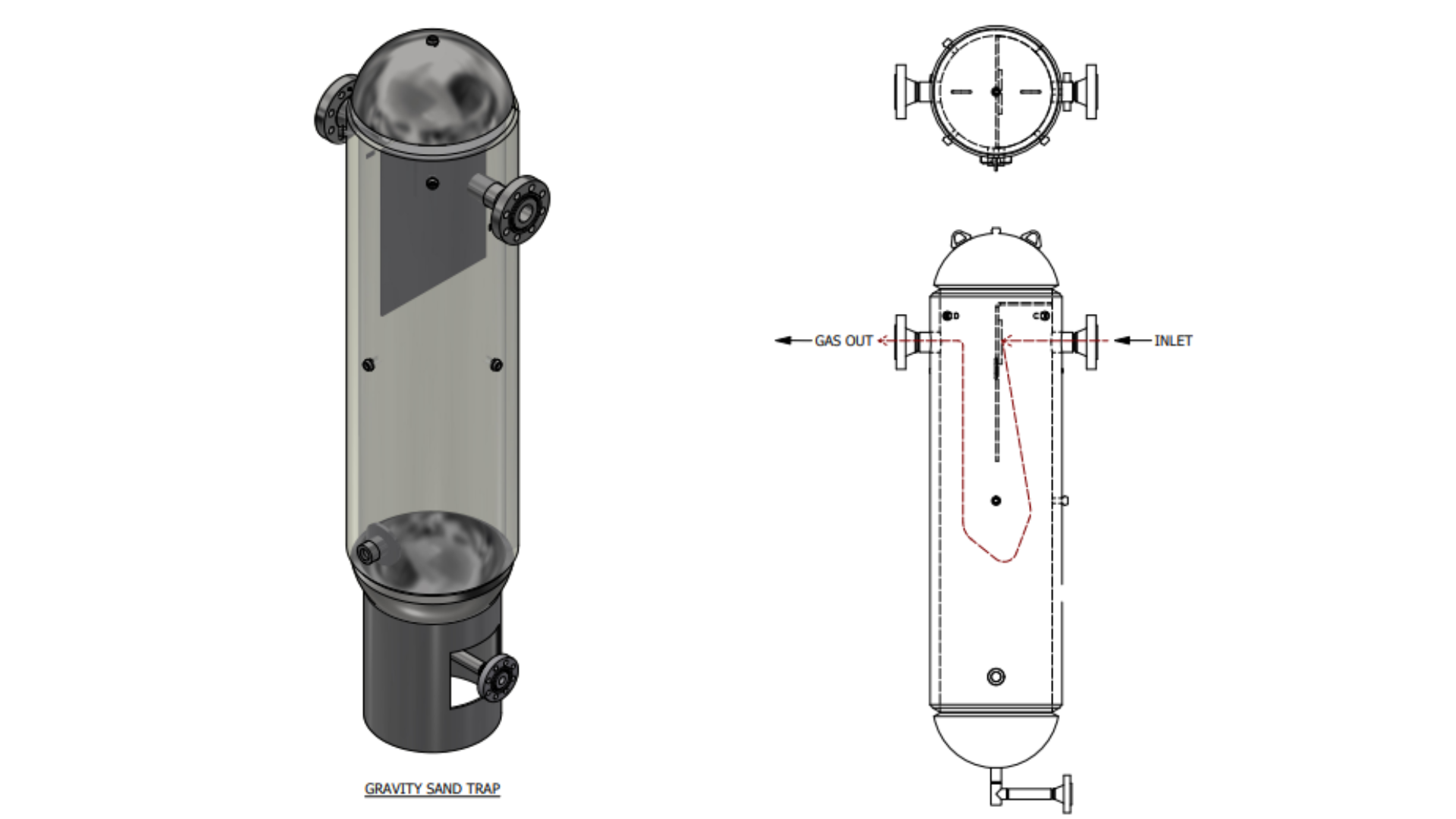

2. Gravity Separators

Gravity separators leverage the density difference between sand particles and the rest of the process stream to achieve separation. The incoming fluid enters a vertical vessel equipped with an inclined baffle. As the fluid flows down and around the vertical baffle, the heavier sand particles settle due to gravity, while the hydrocarbons and water continue to flow upward. The settled sand particles accumulate in the bottom of the vessel.

Gravity separators are known for their simplicity and robustness. They are often preferred in applications where process conditions are highly variable or not well defined; however, they may be less efficient in handling fine sand particles compared to cyclonic separators.

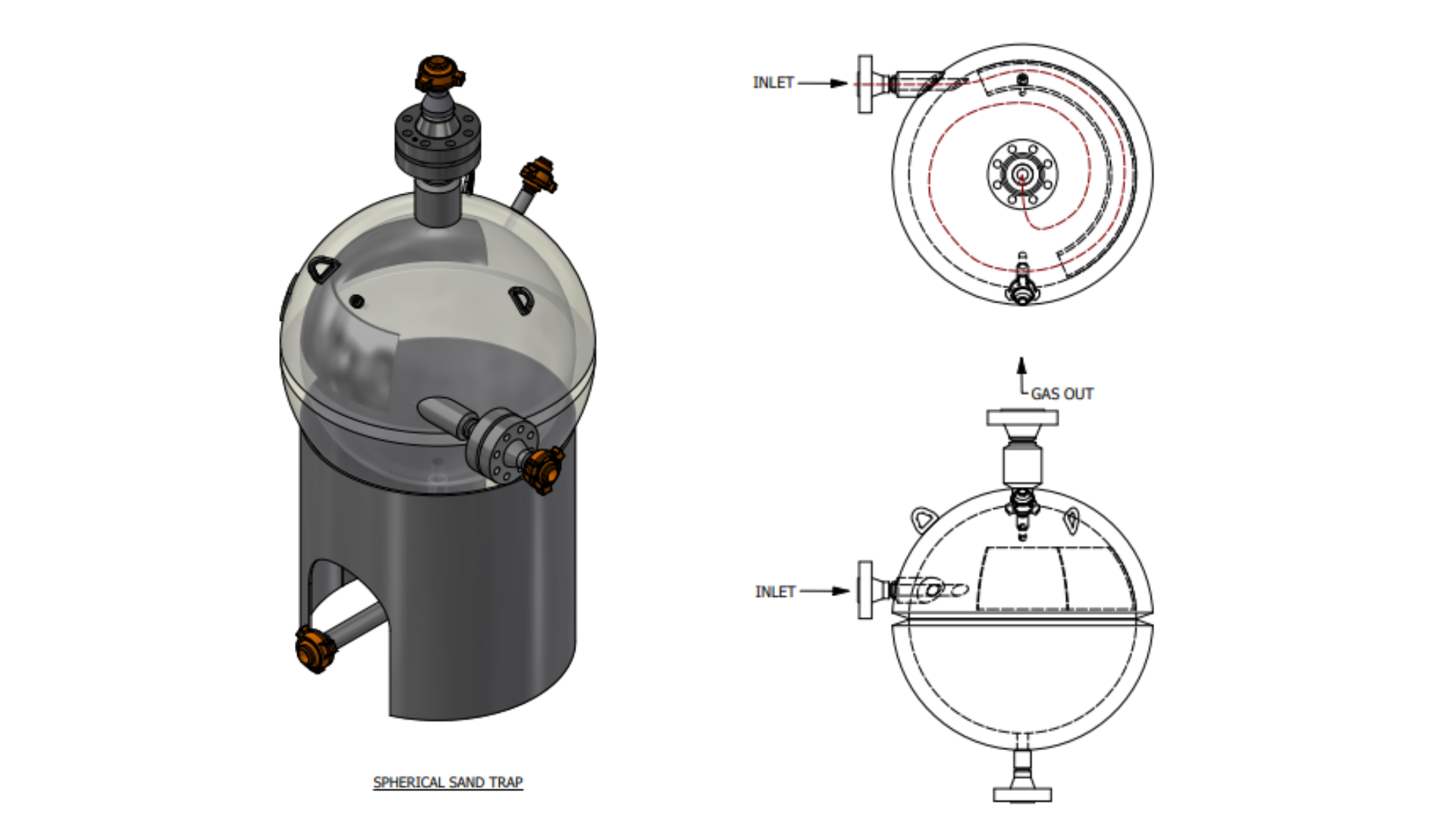

3. Spherical Separators

Spherical separators represent a hybrid design that incorporates both centrifugal and gravity forces to separate sand from hydrocarbons. The incoming fluid is introduced into a spherical vessel, where it undergoes a swirling motion due to the tangential inlet. The centrifugal force propels the heavier sand particles toward the outer wall of the sphere, while the hydrocarbons and water remain in the central core. The settled sand particles then slide down the curved wall and collect in the bottom chamber.

Spherical separators offer several advantages, including high efficiency, compact size, increased sand storage volume, and the ability to handle a wide range of sand particle sizes and flow rates.

The Need for Sand Traps in Oil and Gas Production

Sand particles, entrained in the flow of hydrocarbons, can cause severe erosion and abrasion of pipes, valves, pumps, and other critical components. This not only compromises the longevity of equipment but also leads to production downtime, increased maintenance costs, and potential safety hazards.

Sand separators are indispensable components in the oil and gas production process, safeguarding equipment from the abrasive effects of sand production. The three primary types of sand separators, namely cyclonic, gravity, and spherical, each offer unique advantages and limitations. The selection of the most suitable type depends on various factors, including flow rate, sand particle size distribution, space constraints, and operational conditions.

By effectively removing sand from the production stream, sand separators not only enhance equipment longevity and reduce maintenance costs but also contribute to the overall safety and efficiency of oil and gas operations.

Shop our selection of used and surplus Sand Traps